High-Quality

SIMIKER combining with high-quality materials, top technology and rigorous manufacturing process to manufacture high-quality chargers.

Materials? ONLY the Finest.

Premium quality can only be born by combining strict craftsmanship with the best materials.

Each material used in making our charger is carefully selected by our senior engineers to ensure it’s of top-quality. At Simiker, for battery charger production, we only use:

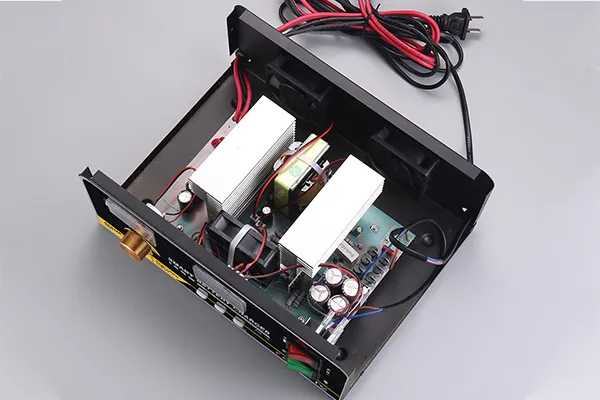

1. High-quality metal housing

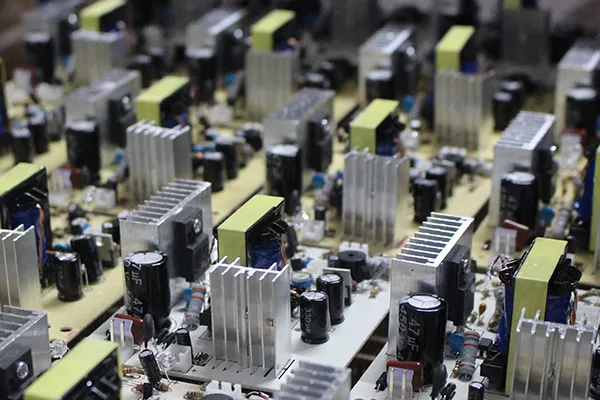

2. Strictly select high-quality circuit boards and electronic components

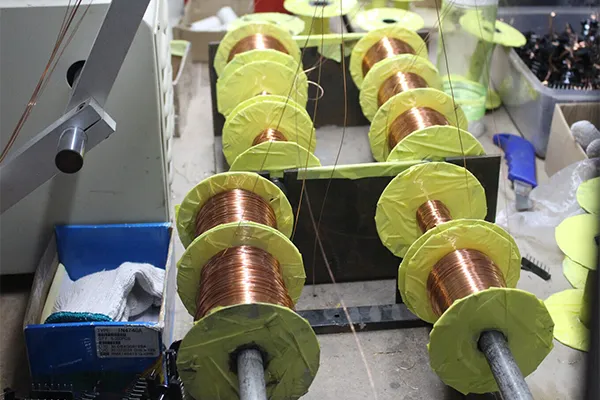

3. Pure copper wire transformer, wound by workers with enough turns

4. Intelligent silent fan, intelligent temperature control adjustment

5. High-quality wire, safe and good electrical conductivity

Production Process

Charger Shell Production

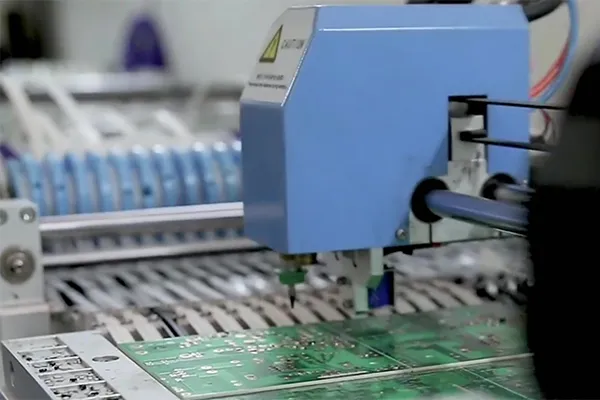

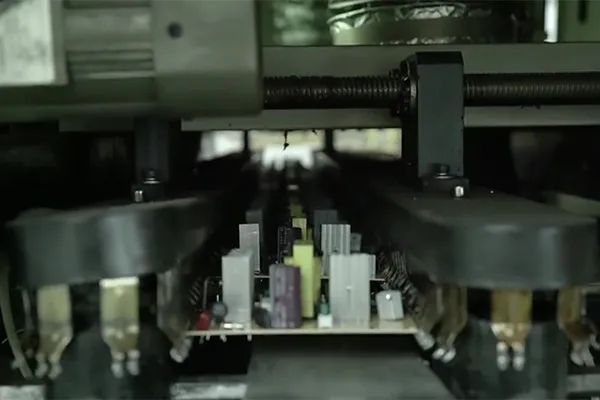

Patch

Plug-in

Wave Soldering

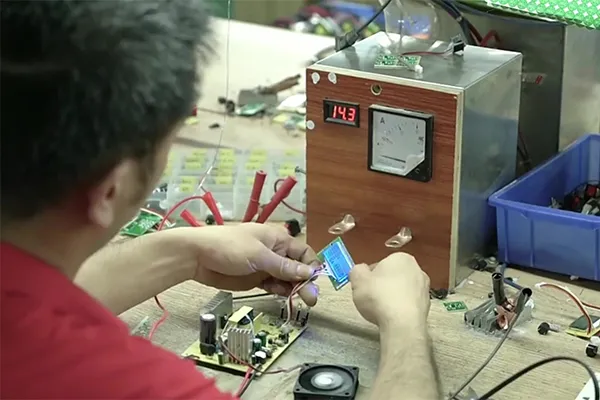

Function Inspection

Assemble

Multiple Quality Control

Packaging

Prepare For Shipment

Guarantee For Consistent Quality

Certifierd By

“We regard the quality of our products as the lifeblood of our business, and excellent reputation is our unremitting pursuit.

We take every charger seriously, we believe that good products can speak. ”

WeiQing

Quality Control Manager